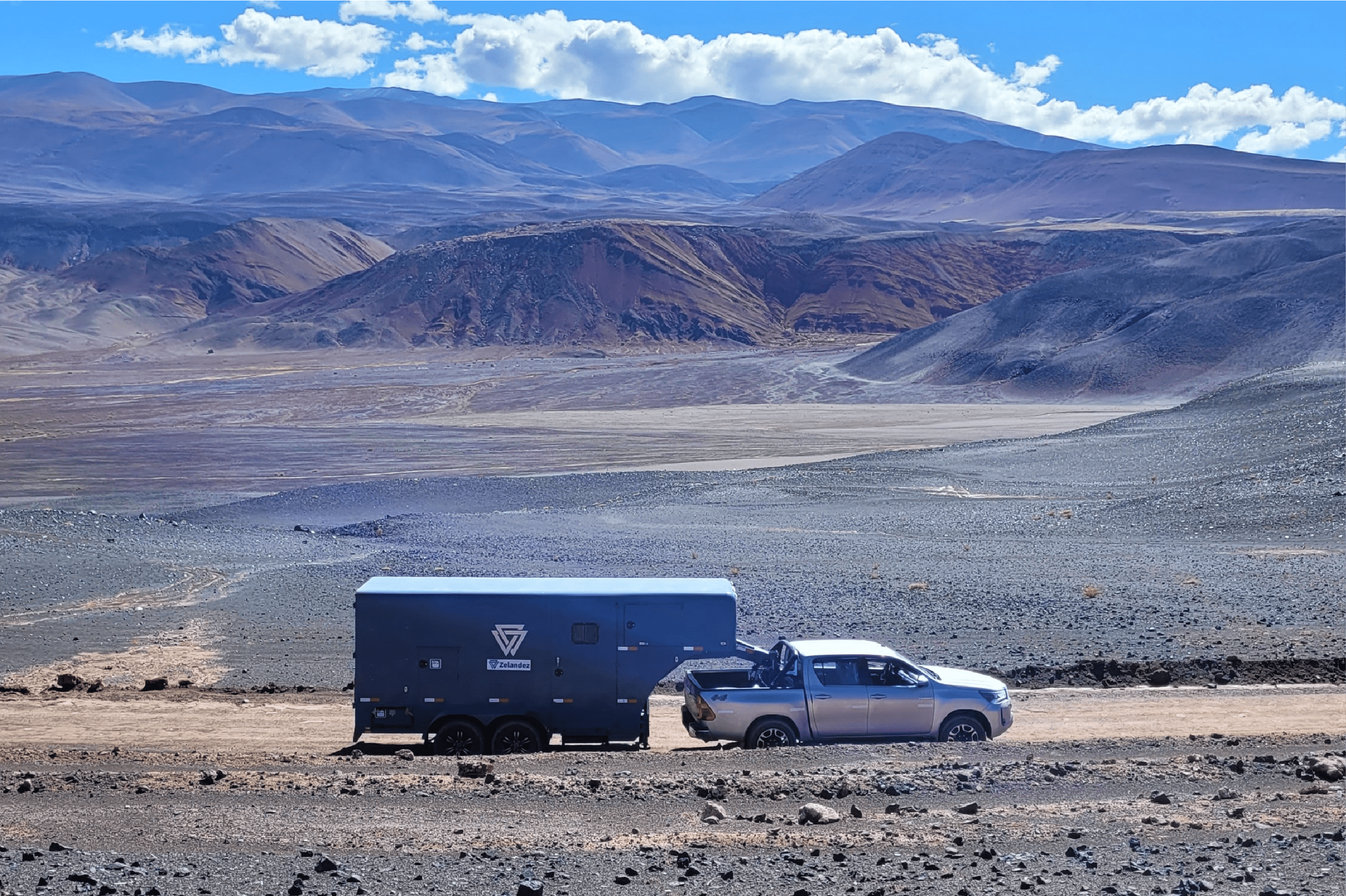

Since 2018, we’ve been delivering advanced technology and people to the lithium brine industry. With operations in Argentina, Chile, Bolivia, the USA and Canada, we serve the majority of lithium brine producers and explorers.

Delivered by world-class people that want the best lithium brine projects to succeed, for a cleaner energy future, sooner. That is our purpose. That is why we exist.

Choose the right specialist solution for your lithium brine exploration programme.

From DLE Selection to Drilling Supervision, we are committed to best practice lithium development.

Use smart sensors and specialist monitoring tools, to produce more lithium with less impact and cost.

Reduce the time it takes to bring new lithium brine resources to market.

Increase the production rate of your existing lithium resources.

Improve your environmental performance and important community relationships.

The use of a Digital Twin is a formidable sounding idea. But is it really relevant, and should the lithium brine market really care?

What is it? The truth is that the term "Digital Twin" is somewhat of an umbrella term, that focuses on delivering results to one of the below key areas:

Practically speaking, that's what they are all about. And these objectives are already being pursued by most lithium brine miners today.

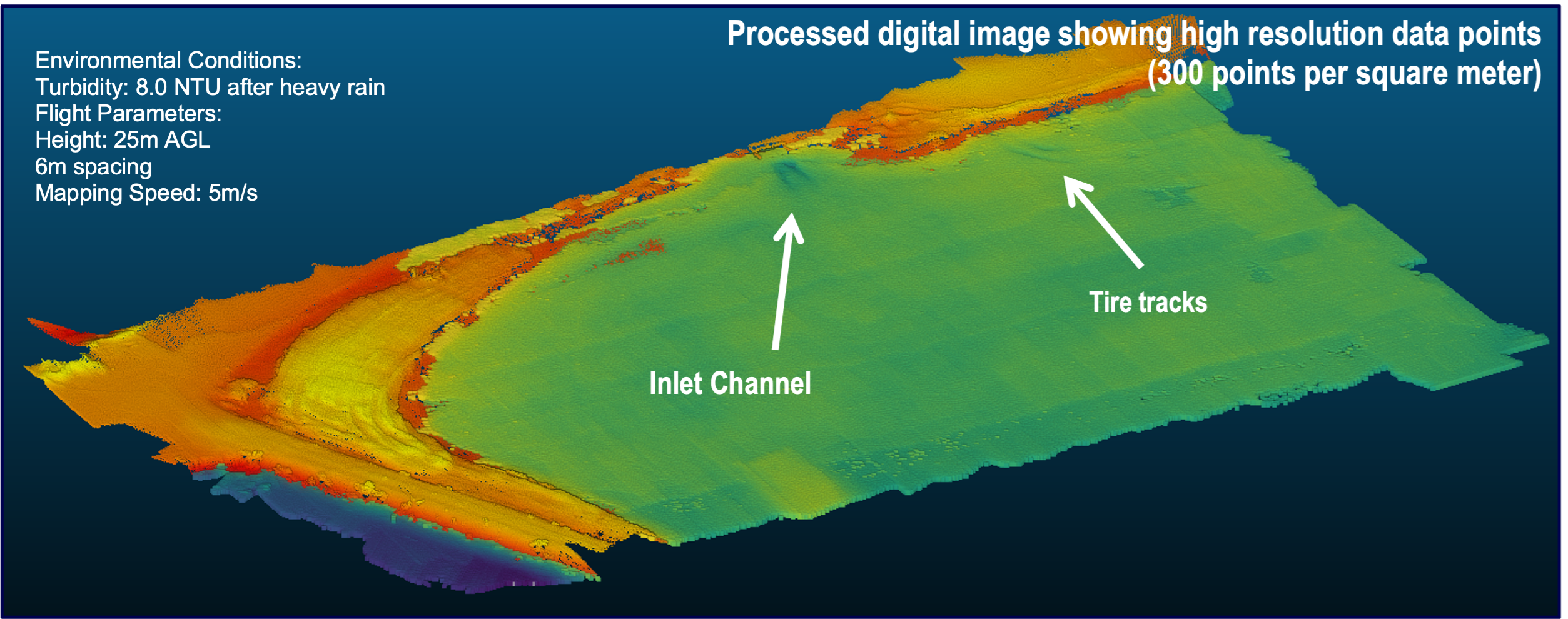

For example, the use of the Zelandez BatSense product. A LiDAR powered drone that feeds data into digital representations of lithium brine ponds, to more accurately represent brine inventory. This more accurate data can significantly impact production performance, and also the efficiency of reagent use.

And with regard to predictive maintenance too. The early use of Digital Twins is happening already, from the brine well-field, right into the aboveground plant.

For example most brine producers use the Zelandez Diagnostics and Recovery service on their lithium brine wells.

The corrosion that can happen to lithium wells over time

By knowing in advance the predicted life of each well, upcoming replacement campaigns can be planned before the loss of production starts to impact project cashflow.

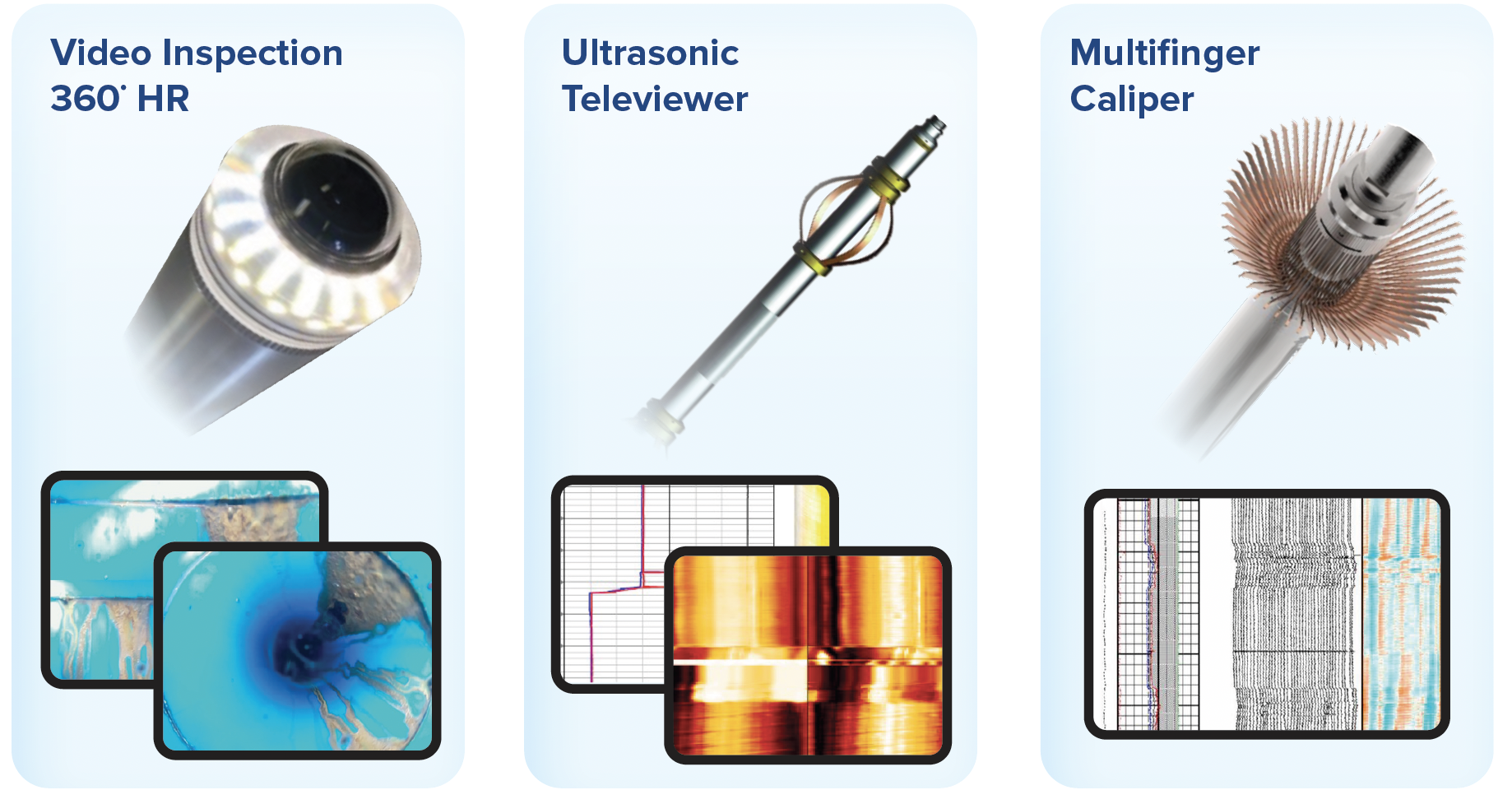

This data itself is gathered by downhole tools that are optimised for lithium brine, feeding into models, so that downtime can be predicted and the stability of the well-field understood.

Tools used by Zelandez in its well Diagnostics service

So in summary then, the term Digital Twin sounds futuristic and new, but it is already happening.

The future is already here.

For more information on Zelandez products, book a meeting with the Zelandez team.

Choose Zelandez for your lithium brine project